Update from Monte Lee 05/01/12: When I wrote this article I assumed that Philips would make a 2700K bulb like the new Philips 1200 Series, 3000K product released as the third generation LED. Not so.

Philips just surprised the industry with a revolutionary LED lamp design for heat management. Patent-pending technology being called AirFlux allows airflow directly over the LED substrate. The design eliminates the heavy heat sink and the “space capsule” look of early generation LEDs. The new design weighs about the same as a comparable halogen lamp. Some older fixtures tended to droop because of the weight of lamps with the old heat sink. The white finish also responds to customer comments that dark bulbs are visually unappealing. AirFlux bulbs are available in quantity as they go through ENERGY STAR certification.

Newest Generation PAR38 LED from Philips

One of my favorite store designers called seeking advice on converting to LED track lighting. She said she read my article in Furniture World Magazine titled, “Path To Sustainable Retail Lighting. LEDS & More” from the September/October 2009 issue (

http://bitly.com/teRcnV), but she couldn’t tell if I recommended LEDs.

LEDs have come a long way and my view today is more positive than when in 2009 that article noted that, “If you are using a 50PAR30 on your sales floor, you might be very satisfied with the new product.” (My personal view is a 50PAR30 generates about 2/3 of the minimum light required to meet the visual requirement for accent lighting.)

Today the direct answer to the $64 question, “Are solid state lighting systems ready?” is still, “Sometimes.” I want to give you an idea of where we are with LED lighting and the three questions you need to answer before you move to LED.

LED EVOLUTION

The evolution in the marketplace of solid state LED replacement bulbs is following the price/ performance curve of LCD and plasma screen TVs. If you were an early adopter of flat screen technology, you probably paid $1,800 to $2,400 for a smaller screen than in the internet capable LCD set I recently purchased for $500. We have more light, better light at a lower cost in today’s LED product then we did just one year ago.

CONCEPTS

The key concepts to understand when evaluating lighting of any sort are power, lumens, CCT, and CRI. Power is basically “watts in” and lumens are a basic measure of light output. Our major lighting efficiency goal is to get the most light per watt of electric power. For retail operations there are other goals as well such as, minimal heat generation and no ultraviolet light. Ultraviolet light wilts vegetables and fades upholstery. You probably already know that halogen display lighting generates 10% light and 90% heat with each watt of input. Other important definitions include:

Correlated Color Temperature: CCT is measured on the Kelvin scale. Noonday sun is around 5000 degrees Kelvin (K) while incandescent light is typically 2700K. Color temperature is based on heating iron (or a filament) so fluorescents, LED and other lighting technologies without filaments have to be “correlated” to that standard. LEDs at 2700K will be similar to incandescent but not identical. Incandescent bulbs get warmer (lower K, more red) and produce less light when they are dimmed. LEDs do not change color when dimmed.

Dimmable LEDs give less light of the same color when dimmed. Another LED fact is that higher temperature LEDs (4100K) produce more light per watt than warmer LEDs.

Color Rendering Index: CRI measured on a scale of 1-100 is also based on incandescent lighting. It is important to keep in mind that you can only compare CRI for lights of the same color temperature. Colors under a 2700K source will look different from colors under a 4100K source. It is fair to compare the color rendering of a 2700K LED to a halogen bulb. We did that comparison at the last High Point Furniture Market and 100% of the furniture retailers who participated, preferred the “look” of the LED.

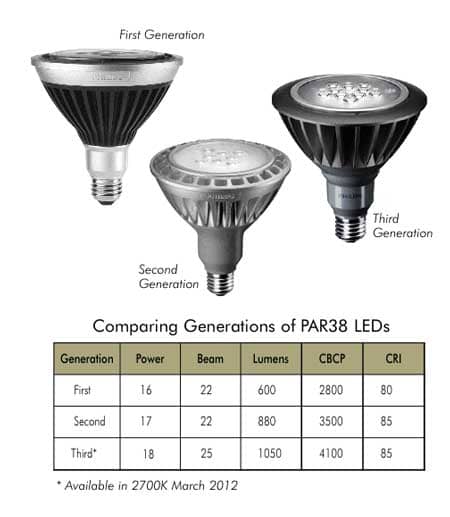

LED Generations

The first generation LED is similar to a 45 watt, PAR38 halogen. By 2010 the second generation was roughly equal to a 60 watt PAR38. That generation is much better, but not on par with the visual standard for most furniture stores which is the 60 watt PAR38 infrared halogen which, because of a special coating, generates 1120 lumens and 5100 CBCP. The third generation is pretty close to meeting that standard and well worth a look.

The chart above adds a couple of new terms to our lighting vocabulary. CBCP stands for “center beam candle power” which is a more useful measure of light output for display lighting than lumens. CBCP gives us an idea of how much light we can put on a target. If the beam angle is smaller the CBCP increases. In the third generation both CBCP and beam angle increases which means a significant increase in output. These third generation LED’s will add “pop” to displays.

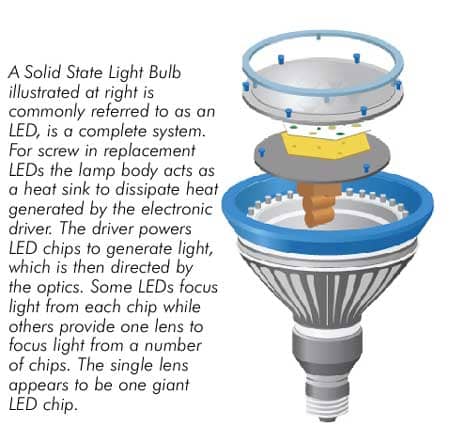

As we move forward with LED we see increased power but we also see increased lumens per watt. The 60-watt halogen infrared generates about 19 lumens per watt compared to first generation LEDs that get 37 lumens per watt. Generation three produces an estimated 58 lumens per watt. The output process depends on the performance of the LED, the electronic driver and the lens. The other major factor is the ability to dissipate heat generated by the electronics. Fins on the lamp body help that.

Should YOU switch to LEDs?

When the third generation LED is available in 2700K we will be able to light any retail furniture display and achieve excellent results. That is my conclusion, but you need to answer three questions to make any lighting system a good business decision.

- Does it meet my visual requirement?

- Does it fit my financial plan?

- What do I know about the manufacturer?

Meeting the visual requirement in furniture means being able to provide product accent or highlighting. Fluorescent lighting can’t do that, but halogen and LED PAR lamps can. I always recommend getting 12 bulbs and setting displays in your store. Let your eyes make the judgement. In most cases the answer is, “Yes, LED meets the visual requirement.”

Occasionally the answer is “Not in my store.” and I can accept that. The “No” usually comes from high-end stores with design services. Interestingly one customer who said “No” preferred the look of LED in the comparison test at High Point.

Does It Fit My Financial Plan?

The second question requires a thoughtful analysis because buying LED lighting for a store is like buying an automobile. It is not unusual for LED lighting to cost $30,000-$40,000 or more depending on the size of the store. LEDs will last 10 years in the typical furniture store. Ten years of halogen infrared lamps might cost $40,500 plus the labor to change them every year. The big savings come from using 70% less electricity with LEDs when compared to the 60-watt halogen.

Saving electricity really appeals to utility companies. Rebates for switching from halogen to LED are $40 per bulb in some areas. Generally that means a 100% return on your investment in less than a year. The store still needs to cover the up-front cost while waiting for the utility to issue the rebate, and that could be a problem. Like the $40,000 car if you can’t afford to buy you can lease. You can also capitalize the lease and take depreciation over the term rather than having a $40,000 expense in the current year. There are ways to make the investment fit your financial plan.

What do I know about the manufacturer?

LED lighting manufacturers include the major lighting companies, start-up operations with little experience in lighting, and some high tech names we are familiar with in other solid state products. Lighting companies are Philips, SATCO, Sylvania and GE. FEIT and TCP are minor players at this point. New companies include Lighting Science Group and MSi. Toshiba is a familiar high tech name but look for others to join in to supply entire bulbs or component parts. CREE makes LED chips for several manufacturers and has some products under the CREE label.

The US Department of Energy (DOE) is keeping watch over solid state lighting in an attempt to avoid all the bad things that happened with compact fluorescents. They have established criteria that manufacturers must meet and have certified by independent labs. One criteria is the ENERGY STAR rating and another is Lighting Facts, a label showing for light output, CCT and CRI.

DOE Caliper reports1 track the progress being made and problems encountered. They find for example that seeing the ENERGY STAR rating on the box or in marketing material may not mean the model number is in the ENERGY STAR listing. The Lighting Facts label has the same problem. DOE reports one product “claims a CRI of 96, but testing reveals a CRI of 82.” LED is clearly a case for buyer beware when the product is labeled but DOE also notes in the Round 12 Summary Report2 (June 2011) that, “For products that do not carry the Lighting Facts label and/or ENERGY STAR rating, only one-third meet photometric performance expectations, and more than one-half fail to meet manufacturer claims for light output, efficacy, CCT, and/or CRI.”

A good rule of thumb is to exercise the same diligence in buying LED lighting as you would with a $40,000 automobile.

And the Winner Is

Department of Energy challenged the lighting industry to develop an LED replacement for the standard 60 watt incandescent. DOE had strict specifications and performance testing that is worth a look (http://www.lightingprize.org/). The reward was pretty good as well -- $10 million in cash, government contracts, and the endorsement of power companies with rebate potential. Philips Lighting North America submitted the only entry in September 2009 and was awarded the prize for meeting all performance criteria in August of 2011.

The Philips product points out something interesting about LEDs. It is hard to make white light from an LED. It is easier to make blue light. The yellow parts of the bulb are actually phosphors that convert blue light from 18 LED chips inside to white light. That proprietary technology is just part of the $4 billion investment Philips has made in solid state lighting.

Are Solid State Lighting Systems Ready?

There are several reasons that make the answer to that question, “Sometimes.” The answer basically depends on whether you like the way merchandise looks in your store. Personally I would switch from halogen to LED when the third generation, 2700K bulb is available in 2012. I believe that the lamp will meet the visual requirement and make great financial sense. Be careful where you make your $40,000 investment. Send me an email for my recommendation.

References:

1. Caliper reports and Solid State Lighting are discussed at http://1.usa.gov/vyrCZL.

2. Round 12 Summary Report (June 2011)—recessed downlight luminaires, track light luminaires, cove lighting luminaires, LED replacements for A-lamps, and LED replacements for linear fluorescent lamps” was used as a source for this article. http://bitly.com/sSSNyQ.

Monte Lee is a Regional Manager for Service Lamp Corporation, a distributor of lighting products such as fixtures, bulbs, plus lighting consulting and design services for retailers. Inquiries on any aspect of furniture store lighting can be sent to Monte care of FURNITURE WORLD at mlee@furninfo.com. See all of Monte Lee’s articles on store lighting posted to the Operations Management article archives on the furninfo.com website.