"No violence, gentlemen- no violence, I beg of you! Consider the furniture!” -Sir Arthur Conan Doyle

I began working in the furniture industry in 1993. I remember my first week on the job at Boyles Furniture in Hickory, North Carolina, as an introduction to an industry that at first took me completely by surprise: I had no idea how much I would grow to love it. The warehouse was sweltering, the furniture was very heavy, the lacquer fumes made me feel like I was going to pass out, and it took a long while, as a Yankee, to get used to the beautiful lilting dialect found in Appalachia. But like a siren’s song, I couldn’t run from it if I tried.

Coupled with that was a dizzying display of the world’s most elegant furniture from such storied manufacturers as Henredon, Kindel, Henkel-Harris, and Baker. The grain of the wood was like a symphony, flashing and changing in color as you viewed it from different angles. Fabrics from all over the world were stretched over frames by skilled and talented artists from Sherrill, Southwood, and Century, so perfectly flow matched you could spend all day looking for a flaw--if you ever found one.

But my initial exposure to the furniture industry would cloud my reasoning for years to come. My standards, cultivated from years inspecting Hickory Chair and Maitland-Smith, did not serve me well when I ultimately transitioned into the mass-produced furniture industry familiar to the other 99% of the globe. All the while I was dancing a vicarious waltz with high-end furniture, the rest of the world was shopping for the basics, reasonably-priced and functional furniture, goods mostly produced in the United States at the time, but beginning to show up in showrooms with labels from countries like Malaysia, Taiwan, and China. More and more, import labels started appearing everywhere, and in the earliest part of this century, domestic factories in western North Carolina began going dark like windows in the Walton house: Good night, John Boy.

Begrudgingly I began finding myself face to face with China. And it took a long time, believe me, but what I came to realize is, this stuff isn’t half bad. In fact, while the finish wasn’t too complicated, just a standard no-rub satin nitrocellulose lacquer, the wood species beneath it was still the same wood species I saw on higher-end goods. Perhaps mahogany was replaced with sapele and khaya, or cherry with alder, but the faux finishing produced essentially the same effect. I started to realize that the big hairy elephant in the room was staring me down, and I’d better saddle up or be left behind.

And then I realized, why do I have to settle for compromising my standards, the very ones I advocate for the customer on their behalf, based on dollar value? It became increasingly clear to me that with customer demand for quality growing faster than the quality level itself, there were going to be a lot of retailers who would be left in the dark unless they searched for that ethereal, magical, intangible netherworld where customers are actually pleased with their purchases.

But come on. Quality isn’t so complicated, and let’s stop using the word so loosely that consumers tune out when they hear it, like the words satisfaction, customer service, and guaranteed. Let’s focus on the gigantic middle-of-the-road of furniture and discuss what you, as retailers, can do to lift yourselves above the competition and deliver true quality furniture.

Hire People Who Know What They’re Doing.

If you try to pigeonhole a delivery driver with little talent and no training into the repair shop, you’re doing him, and yourself, a disservice. A carpenter who quotes a job at 50% lower than the highest estimate in town is usually 50% worse than the best in town. Years of experience are valuable and deserve to be paid as such. When hiring a technician, ask for a demonstration of their skills--a burn-in, lacquering a top, repairing a crushed corner. Ask for a critique of your current shop: What would they do differently? Where is the shop lacking? And yes, their suggestions come with financial costs, but don’t most business decisions?

Look At The Furniture.

This one confuses me. When I open and inspect a piece of furniture, I am looking for anything that jumps out at me, cocked drawers, crushed corners, unfinished edges, glue or oil smears on tops, rub-throughs on the corners of upholstery. If I see them, she will too. Being proactive reduces your even exchange rate because there’s geometrically less to argue about in the home upon delivery. Fewer even exchanges reduces your as-is inventory and eliminates zero-revenue space on your delivery trucks. It also keeps you off the negative social media merry-go-round. Hire someone who understands what the furniture is supposed to look like in its perfect state, and have your technician get it to that perfect state. Doesn’t that seem logical?

Equip Your drivers.

What does a perfect delivery look like? Ask your drivers! Then ask them what is standing in the way of that perfect delivery. As managers, we have to put ourselves in harm’s way and open up about a few things, like... we don’t have all the answers...or, perhaps we’ve failed to give customers what they need. I learn something new every day from the people with whom I work, and I am so blessed to have their input, and exposure to their experiences. Humility makes me more valuable and more capable because I’m open to change.

Sell Quality Furniture.

The most uncomfortable argument of this article, though, can be summed up in this statement: Sell quality over quantity. This topic often ends in disagreement but I’m going to plead my case. Everyone would agree that a piece of solid gold jewelry is superior to a piece of pot metal, gold-plated jewelry, correct? Why? Because when the material is precious, manufacturers tend to put more time into its quality. Conversely, when the end product is made more cheaply, the expectation for the product is much lower. No one expects a $39 import tablet to last, but a $1200 Microsoft Surface Pro 4 better be humming for a long time. Our expectations for the better machine are based, in part, on its price. The quality of the product is usually commensurate with that price.

Generally, furniture quality also rises with price. If you doubt this, think about a $299 sofa. If I buy a sofa to resell at $299, I probably bought it wholesale for $200 landed cost. Whoever made it, though, didn’t sell it to me for cost, they made money on it too. If we assume we all make a decent margin, then the manufacturer may have had $125 in it. Even if they’re vertically integrated, they had to purchase the materials to make that sofa from suppliers, each of whom also earned a decent margin. Let’s tease out the components of a sofa, regardless of its cost:

Deconstructing Your Sofa.

Cover. Typically, a sofa uses about 10-17 yards of fabric. What’s the cheapest fabric you’ve ever seen?

Foam. Have you seen the price of polyurethane foam lately? Especially four inches or more thick?

Dacron. Fiber filling stuffs every back pillow and bolster.

Padding. Dacron sheets typically pad the arms and crown the seat cores.

Frame. Wood has to be straight in order to machine it, and OSB panels, while inexpensive, aren’t free.

Fasteners. Finish staples, construction staples, t-nuts, hanger bolts all cost money.

Suspension. At least ten or twelve sinuous spring strips, with hangers, are used in every sofa.

Construction. All the fabric has to be marked according to template, cut, and assembled properly, panel by panel. All wood components have to be judged, marked and cut by hand. Frame components need to be fitted and assembled by hand. Inside and outside upholsterers need to assemble the entire unit.

Inspection and trimming. Upholstery is messy, and folks need to prepare it for packaging.

Packaging. Even the thinnest bag costs money.

On your very best day, could you even begin to source all of these components for $125? I understand perfectly economies of scale, but what kind of quality is baked into this product? That being said, and considering the laundry list I’ve shown above, are we doing our customers a service or a disservice by selling them something that clearly has very little inherent quality? Are they likely to come back to us after it fails premature to their expectations, and shake our hands? I strongly doubt it.

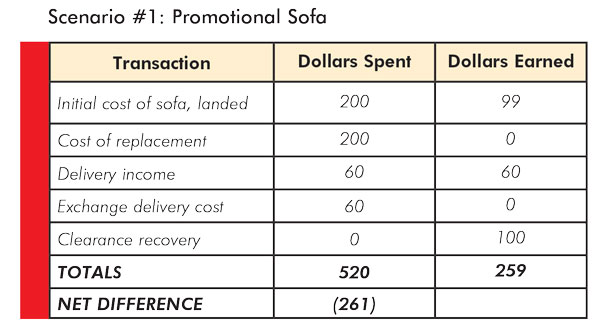

We owe it to our customers to give them the best quality they can afford--but not only to them, to ourselves as retailers. Consider that every piece of furniture we sell comes with a warranty, usually a year. Typical warranties from reputable manufacturers usually cover the frame integrity and some components for a year or more. Going back to my example (see Chart), what was the gross profit earned on the sofa I mentioned, $99 or so, right? If you have to replace that sofa according to warranty--most likely due to a frame separation or failure--that often means buying another one, a fixed price of $200. The delivery fee the customer probably paid was enough to cover your delivery expense, but the exchange delivery cost, maybe around $60, is all on you. The returned sofa has a value of perhaps $100 at clearance if you repair it or not.

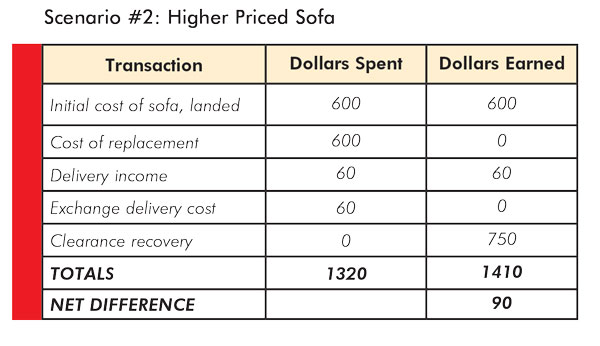

But consider the same scenario for a finer quality sofa, perhaps one with a $600 landed cost and a $1200 price tag. The sofa costs that much because the quality is much better, is made with better materials, and has more features, and therefore can be sold for more at clearance, usually 20% over cost. Presuming a frame failure of an identical nature:

So in the first scenario, we end up with a loss of $261, and in the second, we end up with a profit, although slim, of $90. Even though the first sale was probably a cash sale and the second one financed, you can clearly see the difference in selling quality over quantity.

Furniture quality is not intangible: We all affect it. It begins with how it’s built, but it also hinges on the way we sell it, how we handle the furniture during receiving, how we put it in the racks, how we pull it and stage it, how it’s prepped and assembled, how it’s inspected and repaired, how it’s loaded onto the delivery trucks, and how it’s delivered into the home. No one component of the process can receive more attention than another. Ramping up on prep, assembly and deluxing, but ignoring the delivery processes, is like throwing money into the wind. Equipping drivers with the best touch-up materials and supplies, but loading them up with shoddy merchandise, is equally fruitless. Dialing in on handling is wonderful, but if you don’t have anyone who can repair the defects, what’s the point? It takes a concerted, herculean task to change the culture of any organization to one of true quality, but look at any other team who’s done it, like the Alabama Crimson Tide. Love ’em or hate ‘em, they are the benchmark of their trade. This coming from a Penn State fan.