In the March/April and July/August issues of Furniture World, a panel of industry experts detailed the different kinds of leather, and discussed everything retailers need to know about leather durability, quality, price, repair and service. The entire leather series can be found at

https://www.furninfo.com/series/leather-guide/42.

In this installment Furniture World takes a close look at how furniture retailers can position leather offerings for maximum sales through intelligent advertising and enlightened sales practices.

THE SALES PROCESS

All of the leather specialists we spoke to emphasized the importance of getting good information from customers about how they plan to use their leather furniture.

“Some of the bigger box stores,” Peter Zolferino, President of Omnia Leather, told Furniture World, “don’t spend the time to educate, or want to educate salespeople about leather, and rightfully so in some ways. They might have 100,000 square feet of case goods, leather, fabric and so on, so it’s a lot for their salespeople to learn. Even in some of the leather specialty stores, we see a lack of education, and that’s an area where they can easily improve. If salespeople feel comfortable with what they’re selling, they’re going to talk with pride, and they’re going to be able to educate with confidence. Otherwise, they’re going to shy away from certain products and categories and lose sales.”

“We qualify the customer by first asking them what they’re looking for,” says Ramona Freeze, President of California based R&D Leather Furniture. “We also ask them to describe the room in the house they are looking for. Does it see minimal use or do they really live in it? What’s their lifestyle, and how many people live in their home. Then we ask, how the item they are shopping for is going to be used. Do they like to eat on their furniture? Do they plant themselves in front of the TV and bring in the buttered popcorn? Finally, we ask them what they’re looking for and whether or not they want reclining furniture or stationary. Also, what kind of look they’re trying to get for their room.

“Salespeople need to know about the products they are selling,” she emphasizes, “explain what they sell, whether it’s top grain, full grain, a split or bonded leather. They shouldn’t make the assumption that the customer understands that, for example, what a leather vinyl combination means and how much of that product is leather and how much of it is vinyl. We keep track what customers tell us, including if they want to buy something by a certain date. Since 95 percent of our business is special order, we’ll make a courtesy call to let them know when the cut off date is to get it ordered and ask, ‘Are you still thinking about that piece?’ But most times we don’t need to make the call. They come back on their own.”

Paul Gonzalez, CEO of the leather specialty chain Texas Leather Interiors says his people also ask about the room his customers are shopping for. “Our salespeople ask if customers plan to be eating on their couch, if they have kids and pets that are going to be doing this or that on it. If they need more protection we don’t suggest a completely naked vegetable dyed hide because if their kid spills a Kool-Aid, it’s going to get stained. We spend quite a bit of time finding out about their lifestyle and their concerns about durability. Then, when we have enough information, we suggest hides that best fit their lifestyle. We tell them which ones are cleanable, can be wiped down, and so on.”

Gonzalez also spoke about the poor experiences his customers have had with previous leather purchases. “The tough part in selling mid to high end leather furniture is that we have to describe the difference between the top grade leather, a split and all the bonded stuff that’s available at stores selling leather sofas for $1,299. We really want to serve an educated customer that’s been through that process. They might have purchased a sofa that peeled or they couldn’t replace damaged cushions. There are retailers who mislead customers as far as what they’re getting. I see that all the time. People come in asking if we can repair leather they bought somewhere else that’s completely peeled off, and there’s nothing we can do about that. That’s why we spend a lot of time educating customers about the different types of leather.”

He also told Furniture World about keeping customers. “Great service is the way we keep customers and the referral rate up,” he noted. “When I go into a typical store I see salespeople who aren’t knowledgeable about what they’re selling. I don’t blame customers for going online to do their research and then make an online purchase. We’re finding now that customers are looking for a little bit more of that full service experience, that attention. If a salesperson promises four to six week delivery, says that they are going to have it there on Friday, agrees to get them swatch or make a service call, then they have to keep their word. If you don’t take care of a customer, that one customer will tell 100 people. A retailer can do everything right, but if a salesperson messes up one small thing, it can be really bad for business. So, we stay on top of getting back to customers, keeping them informed through email, and letting them know we’re on top of their order. We let them know when we expect to get their merchandise in, or send out a service call or delivery. This is huge in our industry, for those who want to survive. You want to make that customer experience as enjoyable as possible, always. We try to build customer relationships. I’ve gone back to sending old fashioned thank you for shopping with us notes. We ask customers to send us referrals, and we hope that customers come back to buy some bar stools or a dining room based on the experience they had in the showroom versus a store where nobody pays attention to them and they feel like a number.”

Regarding his company’s sales sequence, Jim Riedl, President and CEO at Arizona Leather Company with 16 locations in California, Arizona and Georgia, notes that, “First our customers select the design that they like. They pick out a particular style because they like the shape of the arm or the seat cushion or the back or whatever it is that tickles their fancy on that particular frame. They could be looking at a sofa, but if they want it built as a sectional with a side chaise, they can do that, and then they can choose from 400 different colors and 50 different kinds of leather. There’s a customization process that they go through. Virtually 99 percent of our sales are custom ordered. We’re very lucky. We have a very professional sales staff. Selecting the leather is probably the biggest concern for our clients, so it’s important to explain all the differences and the types of leather so that they can make a good choice for their usage.

“We’ve found that American made is definitely a big slice of the pie,” Riedl adds. Also, there’s not a lot of choice for consumers to go out and get furniture built to fit their room. They have to take what is offered and they have to settle. So when they happen upon us we have to literally explain it two or three times until they say, ‘Oh, you mean I can build this as a sectional?’”

RETAIL POINT OF VIEW

"There’s always going to be retailers that approach customers on price," observes Stefanie J. Lucas President, HTL International, North America (HTL, Domicil and Muse brands), "But generally when I take a dive into the mind of our target customer and why she buys, price is not always number one. I don’t think it’s the first factor that women consider when they buy furniture. There are other things that are much more emotional that they consider first, such as, does the style represent them? Or, what’s is it going to do to the rest of their home?

"There are plenty of consumers who shop at big box stores for the deal, but there are others who choose independent retailers. These are people who are looking at a store’s image, its look, retail environment and brand identity. In the world of independents it’s the ones that choose a point of view that seem to be the most successful.

"Retailers who aren’t afraid to display product in an interesting manner," continues Lucas, "will have chance of selling the sofa and also those add on items. I don’t think people are afraid to buy bold colors. It’s just a matter of the piece they choose. So, they might not go bold on color for a huge sectional, but will consider it for an accent chair or an ottoman."

When asked about the importance of leather specialists having a point of view, Paul Gonzalez at Texas Leather Company says, "I’m not going to try to go head to head against Rooms To Go.” Instead he observes, the alternative is to cultivate a firm idea of what his store stands for. “We set the criteria for what we carry, the demographics of the customers we are going after, and don’t make any excuses for it. I’m flexible on my margins and try to give my salespeople reins so we can keep price sensitive customers, but frankly that doesn’t always work out and it’s not important to get discouraged.”

He advises, that as a retailer selling quality goods, “It’s important not to loose focus upon seeing a $599 leather sofa at a furniture show. Instead we go back to what we believe in, our market, our niche. We stay fresh on our floor, and constantly move samples. When I opened my own store,” he continues, “I wanted to make it more than just a sea of sofas. One big thing about Texas Leather Interiors is we merchandise aggressively with tons of accessories and tables. We’ve added dining rooms and bar stools, so people really can picture the sofa in their home. We merchandise our stores fully and there’s very little walking room. We try to buy all American."

LEATHER FURNITURE ADVERTISING

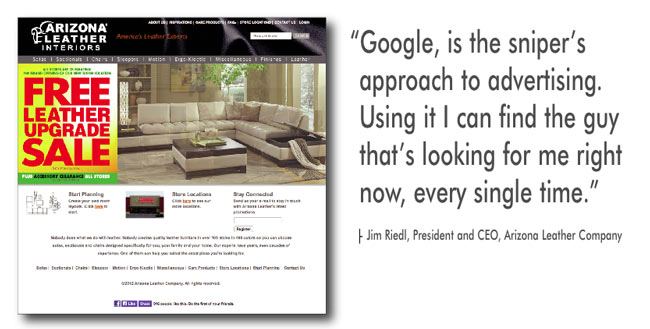

The leather specialists we interviewed have generally trended away from print advertising. “From 1995 up to 2008,” says Arizona Leather’s Jim Riedl, “we advertised in the newspapers, magazines, on radio, and TV. I did postcards and flyers. And in 2008 we all know what happened. I made some severe cuts to advertising, and noticed that my sales, even during the downturn, dropped very, very little. I saved close to a million dollars in advertising, and my sales only dipped 10 percent.

“That’s when I started concentrating on Google. I used to take a shotgun approach, sending my message out across a wide swath of people, hoping one or two pellets would hit a person who was actually looking for my product and my message at the exact time he sees it. Google, is the sniper’s approach to advertising. Using it I can find the guy that’s looking for me right now, every single time. So that’s where I’m spending my advertising dollars. I’ve pretty much cut print out entirely, and my sales are up, drastically.”

“Advertising has changed a lot, reports Texas Leather’s Paul Gonzalez. “We do most of our advertising on Google because we don’t have another good option. We use Pay Per Click and a lot of SEO to get on top of the search results. The trend towards mobile is up every year, and you’ve got to optimize your web site to work on the phone, so people know how to get to you.” I’ve tried fliers and newspapers, but the return is hard to calculate. It’s like going fishing in a big big ocean. We are trying to grab a customer in a certain price range and demographic profile. Grabbing that fish is hard to do. So, instead of spreading out a wide net to look for that customer, we put ourselves in a position where customers can easily find us.”

“Google is constantly evolving,” he adds. ‘We look at our results on a monthly basis. We’ve allocated a big budget for-being on top of paid. We pay about $1.00, $1.50, sometimes $2.00 a click, depending on the market. So it’s expensive.

Paul also notes that the internet is a double edged sword, especially for leather specialists. “The amount of information that people can get in today’s environment is crazy. On top of that, someone can come into our store, see a sofa for which we’ve created value, then Google it, trying find it online for 200 bucks less. There’s a lot of that, and it’s not going away. So, it’s important for us to tell our customers that, we are going to give them service, be here to replace a cushion, and walk them through whatever service they need in contrast to an Internet site based who knows where. We believe there is a lot of value to that.”

Because of this service level, adds Gonzalez, “In the second, third and fourth year of doing business in an area, referrals become really big for us. First we will see somebody’s parents, a son, and then the neighbors. Google is my number one source for bringing in customers, and referrals are number two. Store location is also important. We want to be next to a big box, and in a cluster of furniture retailers because together we’re giving customers an option to make one trip to an area.”

LEATHER FURNITURE ADVANTAGES

Leather has properties which can make it superior to other upholstery materials. Consider the following:

- Leather outlasts most fabric coverings, having a long useful life.

- It will not tear and is half again as strong as other upholstery materials -- even along the seam lines.

- It is fire resistant and emits no toxic fumes, even when exposed to intense heat.

- Modern leather does not crack or peel. It stretches and retains its shape without sagging.

- It "breathes", assumes body temperature rapidly and is instantaneously comfortable.

- It resists heat and sun damage.

- Leather is a practical material, ideal for busy lifestyles. No special solvents or cleaners and no expensive procedures are necessary for its care.

- Leather ages well. It will not wear like fabric covers. Instead, fine leather acquires a "patina" and may become more supple with age.

LEATHER GLOSSARY OF IMPORTANT TERMS

ANTIQUED FINISH: Leather finish accomplished by hand rubbing leather with a dark dye after a lighter base coat has dried, creating dramatic highlights in the finished product.

BATTING: An operation performed on a hide before tanning to remove chemicals such as lime introduced in earlier hide preparation steps.

BICAST LEATHER: See Split Leather. Also known as PU Leather.

BOX EDGED: A square seat front, with either welting or a sewn seam on the top and bottom.

BONDED LEATHER: A fabricated composite material that consists of leather pieces held together on a strong fabric backing united by a pigmented polyurethane coating that is embossed to give a grain patterned effect. Bonded leather may be used to cover entire upholstered pieces or on upholstered sides and backs to reduce costs.

BRAND: A simple easily recognized pattern made by burning the cattle's skin with a hot iron. Used for identification purposes, brands are normally cut out of hides and do not appear on finished furniture.

BUFFING: Hides are often buffed with an abrasive wheel to minimize the appearance of gross surface imperfections such as wrinkles, parasitic damage or healed scratches in the finished product. This process makes leather more uniform, but also obliterates the natural grain and markings that makes each hide unique and naturally beautiful.

BUTTON TUFTED: Buttons sewn through an upholstered surface and tied down. The placement of buttons and the resulting folds produce geometric patterns.

CHROME TANNED: Leather tanned with chromium salts resulting in a soft, mellow upholstery leather.

COATED SPLIT: The lower layers which are ‘split off’ of the top grain layer of a hide can be dyed, finished and embossed to create coated split leather. This product can be thicker and stiffer than top grain leather. Since it is also less expensive, it is often used to cover upholstered sides and backs which do not need to flex and stretch much.

COIL SPRINGS: Wire coils used in quality upholstery to give a desired resiliency and firmness to the seat and back. These are often "tied" or incorporated in a "marshall unit".

CORNER BLOCK: Triangular blocks which strengthen important frame joints.

CORRECTED GRAIN: Top grain leather that has been buffed and sanded to minimize surface marks, then covered with pigment finish layers and embossed.

CROCKING: The physical transfer by rubbing of unfixed dye or loose dyed fibers (especially in suede leather).

DECK: In conventional (coil spring) constructions, layers of padding are added on top of the springs or webbing to complete the "deck" (the area under the seat cushions). In quality upholstery applications, the deck should be well padded, with no bumps or lumps. The padding should extend to the front edge of the deck, completely covering the spring edge or frame.

DIAMOND TUFTING: An arrangement of tufting buttons which yields a diamond shaped pattern on the back of an upholstered piece.

DOUBLE DOWELING: A construction method where two round wooden pegs are fitted into holes in adjacent frame sections.

DRUM DYED: A dying process accomplished by tumbling leather in a rotating drum to encourage the dye to penetrate fully.

DYED TO SHADE (MILL DYED): A finishing system that produces essentially the same color on the suede side as the side on which the pigmented finish is applied.

EMBOSS: To mechanically imprint unique grain effects under heat or high pressure in order to smooth the grain or give a unique patterned effect (ostrich, alligator, lizard, etc.). Top grain leather that has surface imperfections is often buffed smooth and then embossed to restore natural looking grain patterns. Embossed leather is normally less expensive than full grain leathers that retain their natural markings.

FALSE ANILINE FINISH: Leather that’s fully coated with layers of pigment finish that provide antique or tonal effects meant to simulate true aniline finished leathers.

FINISHING: To make leather more durable, clear or pigmented substances are applied to the dyed hide. These provide abrasion and stain resistance as well as color enhancement. The finishing process usually involves three or four coating operations. Generally, the more finish a leather has, the stiffer (boardier) it becomes. Semi aniline leathers tend to be softer than heavily finished leathers, although this can largely be overcome by milling. Other factors affecting softness include the tanning formula and hide quality.

FRAME: The skeleton of an upholstered piece. The frame gives structural support and determines the basic shape of any piece of upholstered furniture. If a frame is unstable, an upholstered piece will not be durable, no matter how fine or costly its design, padding, cushioning or leather cover. Quality frames are generally made of solid wood, but plywood, engineered wood products, a variety of polymers and metal are also used.

FULL GRAIN: A top grain leather that has not been grain corrected, retaining it’s natural markings and characteristics. Animal hides are normally split into a top layer (which had hair on it) and one or more leather layers that are ‘split off’ from the ‘top grain’.

GLATT: Smooth finish.

GLAZED FINISH: A finished leather surface polished to a high luster by glass or steel rollers under tremendous pressure.

GLOVE LEATHER: Sheepskins tanned to be soft, pliable and supple.

GLOVE SIDE LEATHER: Side leather that has a garment finish giving it the feel of glove leather, but with the same general durability as upholstery leather. It is soft, pliable and light-weight.

GRAIN: Markings or patterns on the leather surface. Naturally occurring grain is caused by wrinkles, markings and pores in the hide. Grain can also be simulated through an embossing and finishing processes.

HAND: The softness or ‘feel’ of a leather.

HAND TIED: Single coil springs that are attached to the webbing with links and then "hand tied" to each other and the frame with twine to achieve differing amounts of elasticity in the seat. Two, four, and eight way hand ties may be used. The more ways the spring is tied, the harder the seat.

HARDWOOD FRAMES: Frames made from hardwoods such as ash, oak or birch. These woods are usually kiln dried and resist splitting.

HIDE: A raw or tanned pelt taken from a large, adult animal. Cattle, buffalo, sheep, goat and pig hides have been used to make upholstery leather, but cattle hides are by far the most common.

LEATHER: A hide that has been tanned to render it resistant to decay, as well as relatively soft and pliable.

LOOSE PILLOW BACK: A pillow treatment that can be removed from an upholstered piece.

MARSHALL UNIT: Coil springs inserted in separate pockets and then joined together to form cushions.

MATTE: Dull Finish.

MILLING: A natural softening process that is achieved by tumbling leather in a drum.

MINERAL TANNED: Leathers tanned with any of several mineral substances, notably the salts of chromium, aluminum and zirconium.

MOTTLED FINISH: The result of blending closely related colors to achieve a spotty or splotchy appearance.

NATURAL MARKINGS: The subtle markings on leather are analogous to fingerprints. They distinguish genuine leather from man-made materials. Other marks appearing on the surface of leather are healed scratches, barbed wire marks, wrinkles, brands and insect holes. Gross imperfections are normally cut out of the finished product. Lower priced leathers tend to have many more markings than premium leather.

NU-BUK LEATHER: A pure aniline leather that has a slight nap, but is not a suede. Nu-Buks are top grain leathers that are more durable than suede (made from the split flesh side of the hide). They are aniline dyed, but since they have no pigmented top coat, they may be treated with a chemical that promotes water and stain resistance. Nu-Buk leather should be maintained by occasionally fluffing the fibers vigorously with a suede brush. A damp white cloth can be used to clean spills, which can then be blotted dry. Specialized cleaners are available. Soaps should be avoided.

NUDE FINISH: A leather that is usually vat dyed, but has little or no protective top coat to prevent crocking, cracking or staining.

PATINA: A luster that naturally occurs when uncoated leathers age.

PIGMENT FINISH: The coloring of a hide using a coating containing opaque pigments. The use of pigment finishes insure uniformity of shade and resistance to fading as well as enhanced stain and soil resistance.

PLATING: The process which smoothes the finished surface of leather or produces embossed surface effects.

PROTECTED ANILINE: Protected aniline leather is less expensive and more common than pure aniline or semi-aniline leather. Its coloration is more consistent because it has been coated with protective pigments. The leather’s natural markings are less noticeable. These protected leathers are more heavily pigmented than semi-aniline leather and are actually easier to clean than pure aniline leather because surface pigments repel water and stains... standing up well to heavy use.

PU LEATHER: See Split Leather.

PULL-UP: Aniline dyed leather with an oiled or waxed finish that is pulled tight during the upholstering process, developing areas that become lighter as they are stretched. This result is known as pull-up.

PURE ANILINE: Leather that is aniline dyed but has not been coated with pigmented finishes. It shows all the natural character and markings.

SAUVAGE: A two-tone effect that adds depth to the leather.

SEMI-ANILINE DYED: Term use to describe dyed leather which contains only a small amount clear or pigmented coating (finish). It is a premium product which allowing the natural character of the leather to show through.

SIDE LEATHER: Grain leather which has been cut in half forming two "sides" in order to better accommodate tannery equipment and maximize the use of hides with flaws.

SNUFFED: Grain leather which, in addition to hair removal, has had the outer surface lightly removed by buffing.

SOAKING: One step in the processing of raw hides. Soaking restores moisture to newly received cured hides. This process involves soaking the hide in water, wetting agents and disinfectants.

SPLIT: The term ‘split’ refers to the underneath layer of the hide that’s been split off from the top grain. Splits are usually given a suede or pigmented polyurethane finish, embossed and used for shoes or garments. Split hides are generally thicker and stiffer than top grain leather and may also be used in less expensive upholstered furniture applications on backs and side panels.

SPLITTING & SHAVING: After hides are tanned and excess moisture removed, they are fed through a machine to cut the hide into a valuable top grain portion and split layer. After splitting, the hide is put through another machine to shave it to a uniform thickness.

STRUCK THROUGH: The dyeing of leather can be controlled by the manufacturer to either fully or partially penetrate it. Since full penetration requires more dye, leather that has been fully penetrated is more costly to produce than leather that has only been superficially (the flesh and grain surfaces) penetrated. Leather that has been fully penetrated with dye is known as fully struck through leather. If it has only been superficially dyed, it is called partially struck through.

SUEDE: Leather finished by buffing with an emery wheel to produce a napped surface. Suede is made from layers split off from the top grain portion of the hide.

SUEDED SPLIT: See suede.

SUEDED PIGSKIN: Sueded pigskins are available in garment weight and upholstery weight. The upholstery weight is probably the most durable suede on the market.

TABLE FINISHING: A full pigment finishing system applied on top of a neutral or contrasting color back.

TANNING: A chemical process that converts a raw hide into a stable product. This process is often accomplished in large vats or drums.

TANNING AGENTS: Today's upholstery leathers are tanned with soluble chromium sulfate. Synthetic tanning and vegetable materials derived from plants and wood (bark tanning) may also be used in combination.

THICKNESS OR WEIGHT: Measured in millimeters which, when divided by 0.4 is quoted in ounces.

TOP COAT: Synthetic transparent polyurethane resins applied as a protective coating.

TOP GRAIN: Leather that includes the top portion of the hide... the part that had hair on it. The top grain portion can be processed into full grain or corrected grain leather. The top grain portion of the hide is approximately 3/64” or about the thickness of a penny.

TRIMMING: Trimming, siding and fleshing are operations performed on the hide which remove excess tissue.

TUFTING: See "button tufted".

UNHAIRING: After soaking hides, hair is removed. Unhairing destroys the hair root so it comes free from the hide and loosens the outer skin that covers the grain.

WAX FINISH: Full aniline leather treated with a wax or oil finish that can give it a worn look. See Pull Up.

WEBBING: Interwoven natural (or synthetic) strips that provide a foundation for many upholstered arms, backs, seats and wings.

WELTING: Cord wrapped in fabric used to trim upholstery seams and places where the fabric meets exposed wood.

Russell Bienenstock is Editor-in-Chief of Furniture World Magazine, founded 1870. Comments can be directed to him at editor@furninfo.com.