Strategies used by Bob’s Discount Furniture, Haverty’s, Arhaus Furniture, Levin Furniture and many others.

|

End To End

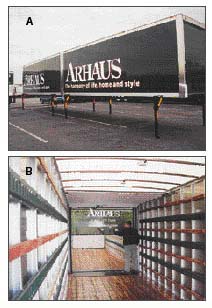

(A) Truck bodies from Ohio based retailer Arhaus shown staged for pickup by local drivers.

(B) Interior view of bodies that have roll up doors at both ends ready to be loaded in sequence.

|

|

Some of our Furniture World readers will remember the days when customers walked the center aisle through the warehouses attached to Levitz, Wickes and other furniture retailers. There were racks left and right with lift trucks darting up and down the aisles. It was a logistics nightmare getting the right inventory to the right store; there were numerous store transfers; excess inventory was prevalent; capital was tied up in duplicated facilities and there were staffing inefficiencies. That business model was proven to be inefficient and today’s market reality dictates that distribution be centralized with service areas of 150 to 300 miles.

Central distribution centers should be located close to the major corridors serving a retailer’s market area. For example, the Sofa Express DC is in Groveport Ohio (near Columbus) and serves locations in Columbus, Dayton, Cincinnati/ Northern Kentucky, Cleveland and Indianapolis. Nearby Interstate highways I-70 and I-71 are the principal transport lanes between Sofa Express’ markets. Local drivers service customers in their trading areas.

Similar strategies have been adopted by Bob’s Discount Furniture in Taftville Connecticut, Haverty’s in Braselton Georgia and Colonial Heights Virginia, Arhaus Furniture in Cleveland Ohio, Levin Furniture at Smithton Pennsylvania and many others.

At their central distribution centers, each of these retailers accrues tangible and intangible benefits for the processes of inventory and quality control, warehouse management, prep or deluxing and facilities. The common denominator for each of these companies in getting product to their customers is the use of Demountable Concepts “Warehouse on Wheels” system.

Two demountable truck bodies are loaded end to end at the distribution center with prepped and wrapped merchandise in delivery stop order sequence. A specialized trailer is backed under the bodies and a semi-tractor transports them to the distant delivery point. The truck bodies are then swapped with truck bodies from the previous day for return to the distribution center. Transport is done during the night to avoid typical traffic congestion. When the local delivery crews come, they back their truck under the body and are ready for home delivery. Product is not touched between loading at the DC and the customer’s home.

Levin Furniture’s Ohio Operations Manager, Scott Frazier, explained that Levin Furniture has nine chassis units and eighteen bodies serving Ohio markets from Smithton Pennsylvania. In addition to home deliveries, they also supply all in-store customer pickups, showroom samples and supplies. Customers have the option to request first deliveries by 7 am which has slashed the number of requested Saturday deliveries. Accountability standards have been established to assure that quality is maintained throughout the steps between prep in Smithton and the ultimate customer. Routine preventative maintenance is all that has been necessary on the equipment.

Todd McDonald, Sofa Express Controller, said that they use standard straight trucks for deliveries within 75 miles of the Groveport DC. Deliveries in Cleveland and Indianapolis regions are serviced with the Demountable Concepts system. Cincinnati uses a combination of demountable units and straight trucks. A variety of product images are used on the truck bodies to show the spectrum of offerings but all carry the company mantra of “Here Today, Home Tomorrow.” Sofa Express really keeps their equipment looking sharp.

Another Ohio based retailer, Arhaus Furniture uses the system to service stores in Ohio, New York, Pennsylvania, Indiana, Missouri and even Florida. Their all black equipment makes a great impression on the highway.

Haverty’s Furniture is using Demountable Concepts equipment throughout the Southeast. Steve Burdette, Vice President of Operations pointed out labor savings associated with the system. “We can use non-CDL (Commercial Drivers License) for our home deliveries. We can improve the quality of our loads and increase the number of stops per delivery truck by 30-40% by using demountables.”

Lee Goodman, Chief Operating Officer at Bob’s Discount Furniture in Taftville Connecticut is a firm believer in the system they use to serve 18 stores in three states. Units are loaded during the day for the next day’s deliveries. Since furniture is loaded directly into the bodies after prep, less warehouse staging space is required. An average of 60 demountable bodies are transferred each night to the stores. Eleven transfer drivers accomplish this logistical move and average 5,500 miles per night. According to Goodman, “We couldn’t accomplish this job at this efficiency without the warehouse on wheels concept. An additional benefit has been the hiring of excellent local drivers within each delivery area to serve our customers.”

Daniel Bolger of The Bolger Group helps companies achieve improved transportation, warehousing and logistics. Questions can be directed to Mr. Bolger care of FURNITURE WORLD at dbolger@furninfo.com.