Reverse supply chain logistics is the practice of controlling resources that are returned, repairable, reusable or recyclable. It’s a catchy phrase for business activities that turn normally wasteful occurrences into profit.

After service return expenses alone can cost 3-7% of a retailer’s sales volume. An operation producing $10 Million in annual revenue can lose up to $700,000 in cost of goods increases due to after-service related expenses. Also, normal facility costs, logistics, and general overhead, produce waste and consume resources. These commonly run up to 22% of sales volume - or $2.2 Million per year for the $10 million retailer in the example above. Finally, negative cash flow due to overinvestment in inventory can be as high as 10% of sales, in this case causing a $1 Million cash reduction. Businesses that continuously work to improve in these areas by reducing operational inefficiencies and waste, become more profitable and add to their cash flow year after year.

This article will summarize 12 practices you can use to add extra profit dollars to your bottom line, through reverse supply chain logistics.

Practice 1 Goods Flow

Maintain efficient flow and handling of customer returned merchandise. Returns happen. However, many operations totally lose control of this inventory. If the merchandise that comes back into stock is not controlled properly and then acted upon, it just sits. The storage and excess inventory costs, plus the loss of vendor credits is costly. To start to improve in this area, create a reverse logistics flow chart with documented procedures. You have standard operating procedures and a flow chart for business going out, right? Well, you should have one for business coming back too. Here is an example of how returns work:

- Return is approved. Credit memo and notes are entered immediately into the management system.

- Pick up or return receipt is generated and signed by the customer and employee.

- Merchandise is scanned and located into a specific return location in the warehouse.

- Returns manager audits the return location daily. Decides on the action to take, i.e. return to vendor for credit, repair and redeliver to customer, repair internally and resell, scrap, donate, don’t repair and sell as-is.

- Assign and move the merchandise to a return in-process location to reflect the reason above.

- Returns manager regularly audits the return in-process locations.

Practice 2 Vendor Credits

Process Vendor Credits efficiently. Systems define outcomes. If you want a desirable outcome with vendor credits, put a manageable system in place. The ball gets dropped here in too many operations due to internal disconnects. The manager responsible for returns must communicate effectively with the manager responsible for issuing and tracking vendor credits. If the product is defective due to vendor defect or vendor damage, take the following actions:

- Audit the merchandise return-in-process area for products for which you are seeking vendor credits.

- Enter and email vendor credit requests into the system with all information required.

- Review open credits that are 30 days overdue, daily.

- Require sales reps to speak with the Service Manager prior to meeting with the buyer.

- Enter vendor credits into your accounts payable system so that future invoices are reduced. Track in a separate ledger account so that your total credits are known.

- Create internal bonuses for total credits received.

Practice 3 Returns Disposition

Sell returns in warehouse. If you have a warehouse or distribution center with extra floor capacity, you may have an untapped Revenue/ Profit Center. Here is what I have seen several businesses do:

- Create an “Ooops” (As-is) section run by warehouse management.

- Move damaged goods or unsaleable floor inventory to this section, immediately.

- Mark-down price to whatever level it takes to get rid of the inventory fast.

- Buy a small number of SKU’s to act as continually advertised items on digital networks: Facebook, Craigslist, Web-site.

- Pay flat commission. Charge full pop for delivery.

Practice 4 Perfect Deliveries

Implement a Perfect Delivery System. Many of the businesses in our performance groups have designed incentive programs for the warehouse and delivery staff. The thought is that the best way to control reverse logistics, is to greatly reduce it. If all products go out in perfect condition with complete customer satisfaction there should be no returns due to damages, right? Here is one form of a Perfect Delivery system:

- Establish a $ weekly bonus for product, picking, preparation, shipping, delivery crews.

- Track all returns that come back due to damages, and all complaints that are delivery/shipping related.

- Reduce the $ weekly bonus by a certain dollar amount for each occurrence of damage or delivery complaint.

Alternately, establish a certain % of Perfect Deliveries required. If the team exceeds this % the Perfect Delivery bonus is paid.

Practice 5 Credits & Rebates

Offer customer credits or rebates for no returns. Sometimes there may be a minor product or delivery issue. In this case, your service or sales manager should be able to offer a certain percentage of sale credit or a similar cash rebate. When considering the resources it takes to process returns and then repair or resend out replacements, it may make sense to the business and the customer to accept the product at a discount.

Practice 6 Warranty Service Sales

Increase warranty, insurance, and protection sales. Businesses that have a high percentage of total sales with extra warranties or product insurance, experience higher gross margin and a reduced risk for return issues. At the top end, some businesses produce over 10% of total sales volume in warranty sales with over 90% of products being insured. Here are some best practices that make this work:

- The business must have a good extended warranty program that is easy to communicate to salespeople and customers.

- Salespeople must believe in the warranty program.

- Sales management must track and train in this area continuously.

- Salespeople must mention the program early in the sales process.

- The salespeople must ask for the sale.

Practice 7 Trade-In Programs

Accept trade-ins in lieu of discounts on the initial sale. In some stores discounting and negotiating are a part of daily life. Although there are ways to eliminate negotiating. Trade-ins can work to actually increase overall margins and average sale size, and help recycle used merchandise. For operations with designated clearance areas, here is how it works:

- Have a set dollar rate for various trade-in products.

- When the negotiation begins, inform the customer that you can discount only 2% if they pay in cash, but you do have a trade-in program where they can receive a $ discount depending on the item being traded in.

- If the customer agrees to the trade-in, ask them if there is anything else they wish to replace in their home.

- Don’t bother to inspect the item being traded in. You win some, you lose some. If done right, you win more often than not.

- Sell the item in the clearance area.

Practice 8 Vendor Returns

Sell Vendor Returns. Manufacturers get returns from retailers. They too need to figure out how to optimize their reverse logistics supply chain. The most common choice for them is to rework, scrap, or resell to retailers at deep discounts. In doing so, product can be priced attractively and at high margins – i.e. 80%. Like clearance centers and trade-in programs, this practice is not for everyone, but for the right type of operation it can yield decent returns.

Practice 9 Electricity

Reduce electricity usage. Seek efficient power sources. This can be a one-two punch with solar power and efficient internal lighting. Operations can receive these benefits:

- Tax credits for Installation.

- Reduced operating costs.

- Positive exposure in your community for being a green business.

Practice 10 Delivery Crews

Reduce vehicle and delivery crew costs. The biggest causes of inappropriate vehicle expense are not filling outgoing resources to capacity and inefficient routing. Here is how best-practice companies operate:

- Trucks should be at capacity every day. Make sure you are running the proper number of vehicles and crews.

- Ensure they are zoned properly (going to the same area or along the same route).

- Customer delivery add-ons are found to bring trucks to capacity. Add-ons determined by zip code.

- Use a web-based routing and GPS tracking system to help define route, manage remotely and improve communications with customer/crews/management.

- Proper delivery windows must be given to reduce driver idle time.

- Require crews to call customers before delivery, and deliver sooner if ahead of schedule.

- Consider paying crews by the load, stop or % of sales as opposed to by the hour.

- Charge the appropriate amount to the customer to cover delivery related costs.

Practice 11: Recycle

Implement a plan to recycle packaging materials. Efficient companies do not allow cardboard, styrofoam, and pallets to stack up. Machines to compress foam and bind cardboard are readily available. The byproduct of these can then be sold and subsequently used by others as raw materials. Even old pallets can be turned into a rustic/urban material for showroom display props.

Practice 12 Inventory Control

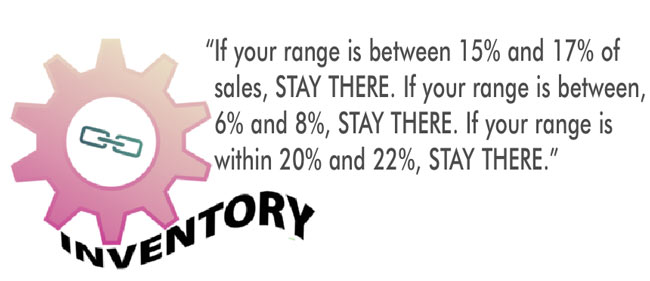

Carry the proper amount of inventory. Perhaps the biggest waste of resources is excess inventory, costing money, time, space, materials, and energy to move around and store. If you want to have the biggest impact on the environment and your business, don’t be excessive with merchandise.

Figure out a range of what dollar amount is appropriate for your sales volume on average and STAY WITHIN THAT RANGE. If your range is between 15% and 17% of sales, STAY THERE. If your range is between, 6% and 8%, STAY THERE. If your range is within 20% and 22%, STAY THERE. To stay within your responsible range, you should develop systems and procedures that:

- Use open to buy parameters for new merchandise purchases.

- Flow bestselling items fast.

- Do business with vendors that ship efficiently – lead time, quality, and reliability.

- Use an ongoing inventory reduction system for stagnant items and do not let merchandise remain idle.

Conclusion

Take time to review your reverse supply chain. Ask yourself, “Is there a way we can be more efficient with our resources?” In doing so, you will find some hidden profit areas in your business that you can tap through controlling resources that are returned, repairable, reusable or recyclable.