Do you recall the last time you spent time out on the receiving dock? In a half hour review, you may be surprised to learn there are problems that ultimately compromise customer service and profitability. The root causes may be your own internal processes, the trucking company that delivers your stock or your vendors. I encourage you to spend some time in the warehouse receiving area and observe the real problems your people are seeing.

You may find that although you had excellent procedures in place at one time, but there has been employee turnover without adequate training, employees have gotten lazy, or receiving volume has increased resulting in an understaffed situation.

It makes no difference if you are using a manual system or a state of the art order processing system. The challenges of running an effective receiving operation are the same as in pre-computer days. The long supply chain from off-shore manufacturing requires much more attention to origin packaging and handling. There appears to be an industry –wide disconnect between purchasing and receiving personnel. Your business is furniture retailing, not furniture repairing, but we continue to see far too many damages at receiving including concealed damage. Does anybody recognize that your customer service goals cannot possibly be met when so many damaged products arrive at your warehouse? As you observe each of the following items on the checklist, my suggestion is to grade each item from one ‘Bad’ to five ‘Excellent’ to identify opportunities for improvement. Then discuss each item with your management team and take appropriate action.

1. Staff Training:

1. Staff Training: Many receiving employees want to do a good job, yet have limited reading or language skills. The best training materials are very basic and intuitive. Check to make sure they can be understood by the people actually doing the work. If some of this work is being done by day labor, it must be even simpler with additional controls.

2. Advance Shipping Notice and Purchase Order on File: Whether electronic or manual, timely access to this information is more productive than blind receiving.

3. Dock Area Clear and Organized: Having adequate space to segregate receiving by lot is essential for control and to minimize theft risks.

4. Arriving Truck Load Quality: As trucks are backed up into the dock, products should be stabilized. Fallen over cartons are a sure sign of potential damage. Load condition should be noted on the bill of lading.

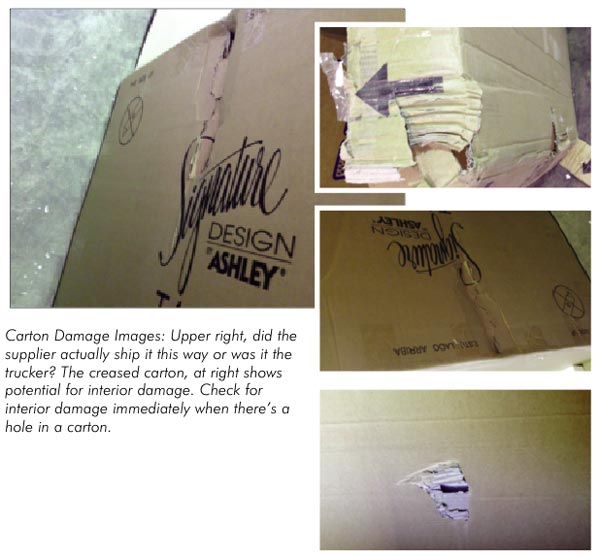

5. Obvious Carton Damage? Identify your processes to handle damages at receiving. Noting “received subject to inspection” does not protect your rights. It is necessary to note the specific indication of damage and take photographs for possible claim filing. A worst case scenario is to receive special order merchandise, to call the customer for a delivery appointment, and then find there are problems. Your internal procedures should initiate timely action to insure customer satisfaction. If the damaged item is part of a larger order and you choose to make a split delivery, your out of pocket expense may exceed the margin on the entire sale.

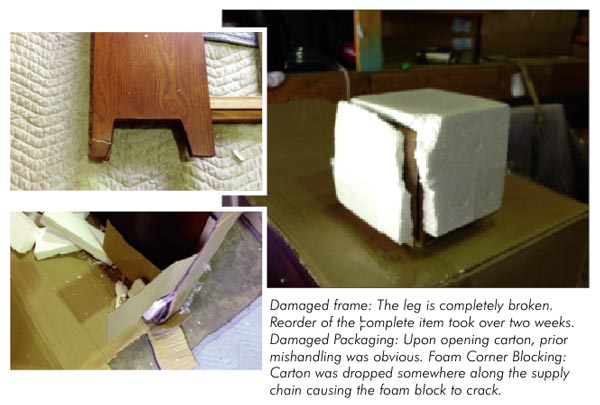

6. Concealed Damage?

6. Concealed Damage? The standard time to file a concealed damage claim is 15 days and your efforts to collect are more difficult unless your internal handling is excellent.

7. Merchandise Received to Dock, Transferred to Storage, and Daily Dock Report: If you start the day with a clear dock, receive to a dock location, and then transfer to the storage location the same day, you have an opportunity to increase control. It’s easier to review transactions from one specific day than to search for items received weeks ago.

Bottom line, reconciliation of the physical receiving processes to your company’s financial records is essential. Take time to visit the dock and perform this mini checkup to identify potential weaknesses in your operation so you can resolve them or seek assistance for a thorough operations review.