Part 2- How furniture retailers can apply Dynamic Inventory Management principles in real world situations to generate more cash and profit.

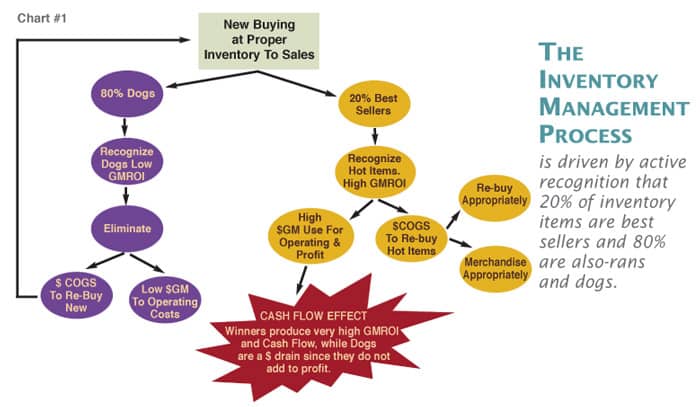

Editor’s Note: In the December/January issue of FURNITURE WORLD Magazine, David McMahon looked at Dynamic Inventory Management techniques. His article described key inventory metrics that should be regularly checked. It also outlined a process for keeping best sellers in stock that is driven by active recognition that 20% of inventory items are your best sellers, and 80% are also-rans and dogs. This article can be found on the www.furninfo.com website in the operations article archives. This month, the discussion will continue by looking at how to execute dynamic inventory process in the “real world” by defining the task, assigning responsibility and clarifying objectives and taking measurements.

Best Sellers, Dogs & New Items

To execute the dynamic inventory process described in the December/January issue of FURNITURE WORLD (see Figure 1) you must first, spot your best items, categories, and vendors.

Even though best sellers will only represent 20% of your items, it is impossible to remember each one of them in their different product lifecycles. That’s why you need to analyze and sort items monthly by gross margin written over the prior six months. Make sure that you have these items in stock, displayed properly, and on-order in the correct quantities.

Take steps to keep them in the forefront of your employee’s minds. Salespeople should know which items are best-sellers and where they are located, because these are, typically, the easiest products to sell. Your buyers should continually track hot items. Warehouse and merchandise managers must take care to display them promptly in all relevant showrooms.

As well, you should analyze, in summary, the GMROI for each vendor and category, then compare your results to the industry averages publised by NHFA. Each item belongs to a vendor and a category, so you can determine where your strengths and weaknesses are. Doing this on a monthly basis will help you to spot trends and measure the effectiveness of your inventory management strategy.

By spotting your best categories, vendors and items, you establish a re-purchasing priority. When you have this important information at your fingertips, you can buy hot items when they are needed.

The greater the in-stock days of your best sellers, the greater your GMROI and sales from those items will be. Customers often want and expect immediate fulfillment of displayed items, so best sellers should be kept in-stock at appropriate quantities. Dogs can be sold off the floor any time, as is.

New items are the only exception. When you are testing a new item, it is appropriate to keep it nailed down. Stock-outs of best sellers can be a major downside of buying new items before hot items. Once you have identified your best sellers, look at these primary factors to consider when reordering:

•Rate of sale over the prior six months.

•Available in-stock and available on-order.

•Reorder lead-time.

•Reorder minimum.

Commonly, buyers meet with reps and make decisions based on factory data and intuition. This is generally not a good idea. All purchases should be backed up by your data - not someone else’s information or a gut feeling. Factory data typically does not contain detailed retail selling information. Your suppliers cannot properly identify your best sellers by GMROI. Neither can they tell you the correct time to re- purchase.

Flushing Dogs

Equally important as spotting hot items and purchasing them, is identifying your slow moving items so that you can flush your dogs.

Tracking dog merchandise is even more challenging than tracking winners. Winners almost take care of themselves because everyone loves them – or should. Dogs however are commonly ignored. They clog up your showroom and take extra warehouse space. They strangle your profit and cash flow by limiting your ability to re-purchase new items that may have become best sellers. They force your organization into dog stagnation.

To get out of this retail trap, implement an inventory aging system. As mentioned before, a fast turning store will have over 75% of their inventory value current (new items less than 60 days old and best sellers). To get started, set six aging periods on your furniture categories where each period is 60 days long.

This is a step approach to inventory reduction. It allows you to maximize GMROI by recognizing and taking action on dogs faster than a semi-annual clearance sale, for example. Here you will gain in both turns and gross margin.

When companies age their inventory out every 60 days for the first time, many are shocked by the realization of how old their inventory really is. Current inventory may be so low that the system is un-workable due to the large number of old items requiring immediate attention. If this is your experience, set your aging dates out far enough to produce around a 75% current inventory. This allows for a more manageable start to the system.

At each aging period, identify dogs and take specific actions. These actions can range from simply marking them down by 10% per period, to taking steps such as re-merchandising, spiffing salespeople, un-nailing display, packaging, advertising, and moving items to clearance centers.

Regardless of the actions you take to solve your never-ending dog challenge, your goal should be to identify these items and do something so that you don’t succumb to dog stagnation.

Each month, execute your aging system. As your current aging increases, shorten your aging days to turn inventory faster.

If you flush out your dogs, while purchasing new items at the correct time, you will sustain a profitable level of inventory. After you achieve this, Leverage your systems for new buying.

New

New

Buying

So when should you buy new merchandise and how much should you buy?

Once you have all your best sellers on order, you need to try new items if you are under your target inventory to sales ratio. This number has typically ranged from 15% for high profit companies to 20% for average performers. Companies that consistently operate at these levels typically have the cash to buy new.

Dollars for purchasing new come from the cost of selling items that did not work out - dogs (see Figure 1 explained in more detail in the December/January issue). The margin made on these items should go towards operating costs, while the cost (COGS) should go toward buying new merchandise.

For example, if your company has a desired inventory to sales ratio of 18% and you find that you are below this level, start tracking the cost of your dogs sold through your inventory aging system. Put this value either on a spreadsheet or into a real bank account. Make this fund available for “open to buy new”. When you go to furniture shows or meet with reps, you will know how much you have available to spend. Following this rule, you will not become over inventoried provided that your sales are constant. If you use more funds than are available, you will eventually lose cash flow due to the odds of the 80/20 rule of retail that says that 80% of your new purchases will be also-rans and dogs; only 20% will become best sellers.

A word of caution; don’t fall into the trap of buying new in anticipation of selling your dogs within the product lead time. This practice almost never works, and a shortage of cash will be the likely result.

Once you know how much you have in your “open to buy new account”, you will need a system to help you find which new products you should buy.

If, for example, you have $20,000 in an open to buy fund, you should look to areas that are currently performing with an above average GMROI. The best way to do this is rank your vendors under each category by gross margin dollars and look at the GMROI of each vendor. Invest in your highest producing area. For example, if your bedroom case goods category has a high GMROI compared to the industry high profit standards and your other categories, this is a good candidate for new investment. Once you’ve identified the category, take a look at your vendor rankings in the category.

You will most likely have one or two vendors that are out-performing all others in GMROI. Finally, look at your current lineup with respect to your price points displayed to see if you are sufficiently covered. Put your money in areas of strength and watch the numbers closely after the merchandise arrives.

After making the decision to purchase a new product, you need to closely follow its dynamic product lifecycle. New merchandise is for testing. The objective is to put the product in front of your customers to gauge their response. If they like a new style, it will become a best seller in your ranking system. If not, it will show up as a dog in your inventory aging system.

Even if your new product is a potential winner, it is still necessary to treat new items properly to maximize your GMROI. Don’t buy new products and forget to look after them. Follow these important operational steps to ensure the proper testing of your new items:

•PO Follow-up – Acknowledge all PO’s, without exception. Verify your orders, check costs and determine ETA dates. Your purchasing clerk should produce a non-acknowledged report weekly to see what is falling through the cracks.

•100% Inventory Accuracy – If you are above 3 million in annual sales, you should be bar coding. Otherwise you cannot fully benefit from inventory management due to the high probability of error in quantities and locations. Receiving needs to be immediate and locations exact – period.

•Fast Display – Your merchandiser and buyers need to request and display new merchandise within 1 week of its arrival. Print a report each Friday for merchandise that is available to be displayed for that weeks’ receiving. This will improve your turns.

•Proper Pricing – Once your merchandise arrives and the actual landed costs are calculated, your buyer should physically look at the product and price within the proper price point. By doing this you will gain additional gross margin.

•Nail down – Your merchandiser and sales manager should ensure that new items will not be sold from the floor during an initial test period (usually 60 – 120 days).

•Proper Display – Display and accessorize in a high traffic area to maximize customer exposure.

•Sales Training – Your sales manager and reps should train your employees on the features and benefits of each new group.

•Tracking & Analysis – Have sales manager and buyers keep track of new items systematically and discuss results at least each month.

•Fast Delivery – Your delivery scheduler needs to schedule in stock items for fast delivery. Make sure that you get and review reports of sales that are fully deliverable.

•Don’t Forget Proper Accounting – Many companies do not accurately cost their merchandise. It is imperative that your office manager check your invoice cost against your receiving cost and adjust where necessary to make sure that you have the correct information for your decision making.

Managing Inventory Change

Daily operational excellence with dynamic inventory management will maximize your cash flow in the long run provided that you are committed to managing the process.

Following-up with the right people is a key to successful execution. As discussed, the dynamic nature of inventory management is about managing changes in the merchandise lifecycle. Several individuals in your organization will need to become involved, and it is your responsibility to ensure that each individual is performing their tasks efficiently.

•Follow-up often!

•Continuously review the inventory lifecycle process.

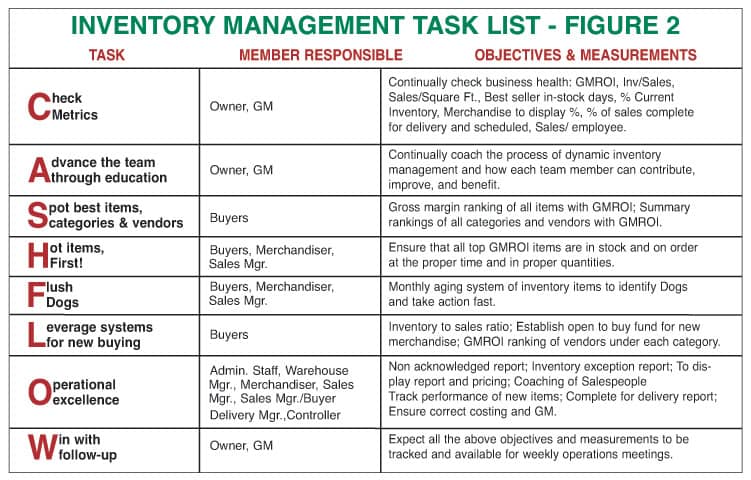

•Develop a task list similar to the one in Figure 2 that specifies each task, the team member responsible and the objectives and measurement to be taken.

Finally, inspect what you expect! Have weekly operations meetings with your team and require them to report on their performance. Have the metrics, reports and data to back it up. If people are missing their target, identify issues and find a solution --- fast. Your employees will know what is expected of them and see their performance as being a critical part of your company’s success.

Everyone will benefit from improving your dynamic inventory management process. Your customers will get more selection, more available items, greater value and faster service. Your employees will get a more rewarding work atmosphere, better day to day procedures, a faster turning floor, and a more secure company to work for. As an owner you will see your company generate cash and profit faster and you will be able to compete more effectively in today’s tough retail environment.

David McMahon is a Senior Business Consultant for PROFITsystems, Inc. PROFITsystems delivers a "Total Success System" through PROFIT professional, PROFITconsulting, PROFITgroups, PROFITuniversity, PROFITfreight, and PROFITservices. These business units offer best-practice solutions designed to maximize cash flow and profitability. Questions can be sent to David care of FURNITURE WORLD at davidm@furninfo.com.